Forklift fuel types: gas or electric?

Forklifts can be categorised according to which sort of fuel they use, of which there are four main options: diesel, petrol, gas, and electric. In this article, we’ll be focusing on two forklift fuel options – gas and electric – and seeing how they compare.

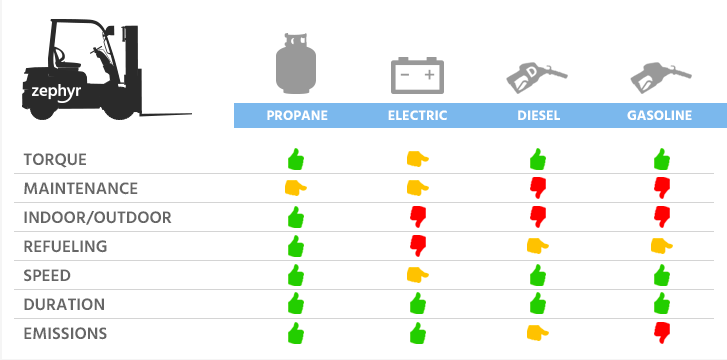

Font: askzephyr.com

Electric forklift fuel

Electric forklifts works with a battery, making them the most environmentally friendly form of forklift. Battery powered means that they are well-suited to work indoors, in cold storage or in food processing related environments where the fumes emitted by other kinds of forklift would be problematic. Electric forklifts are available in various sizes and voltages – for example, Toyota have four different models able to lift up to 8.5 tonnes – to meet a variety of needs.

Electric fuel advantages:

- Environmentally friendly option

- Produces low levels of noise during operation

- Can be used in many areas, including indoors, small spaces, food processing environments and cold storage

- Excellent manoeuvrability and stability

- Simple controls

- Cheap running costs, compared to other fuel types

- Simpler design with less moving parts means easier repairs

Electric fuel disadvantages:

- Batteries can take a long time to recharge which can be problematic if you operate 24 hours a day – having another battery to swap in is a good solution but is another cost

- You will need a battery charging station; this should meet certain conditions such as being dry, well-ventilated and temperature controlled

- Shouldn’t be used in overly wet conditions as water seepage could affect electrics

Gas forklift fuel

There are two main types of gas forklift, liquefied petroleum gas (LPG) and compressed natural gas (CNG). LPG forklifts are a very popular and versatile choice which run off a mix of propane, butane and other chemicals. CNG forklifts are also an efficient and durable choice, albeit less widespread than propane forklifts, and are fueled by filtered and compressed methane.

Both options are ideal for outdoor usage, are powerful and great for a variety of work. Gas forklifts are made in a range of sizes and capabilities which can be seen in the choice available from manufacturers such as Jungheinrich.

Gas fuel advantages:

- Burns cleaner than alternatives, such as petrol, producing no soot and less pollutants and emissions

- Safer and quieter than petrol or diesel fuelled options

- Widely available

- Lower maintenance costs compared to other fuel-powered alternatives

- Refuelling is quick and easy

- Powerful and reliable operation in many conditions

Gas fuel disadvantages:

- Fuel consumption is higher than for petrol

- Slightly less powerful than liquid fuel alternatives, i.e. petrol and diesel

- Due to the pressurised tanks and flammable nature of gases, this can be a dangerous fuel if stored incorrectly or if the tanks get damaged

Gas vs electric forklift fuel

Your choice between a gas or electric forklift fuel will depend on several factors, including the conditions of your workplace, use the machine indoors or outdoors, the power needed and the size of loads to be handled. Generally, electric forklifts are more suitable for indoor usage, tight spaces and controlled environments whereas gas forklifts are superior for outdoor usage and larger loads. Giving good thought to what you need the forklift for is the best way to ensure you choose the right kind for your needs.

Euro 1 Training are experts in plant machinery, offering thorough, high quality training courses for customers in and around Sheffield, Wakefield and Goole. Our accredited courses are delivered by experienced course leaders and involve both theoretical and practical training. After completing certification on your chosen piece of plant machinery – from forklifts to HGVs – you will have all the necessary skills to become a proficient operator. Get in touch with our helpful team today for more information.